One of the most intriguing companies to emerge during the era of the Covid-19 pandemic has been Norway’s Naukatek, which is currently planning to launch an entirely new product range of high performance materials based on meltblown nonwovens.

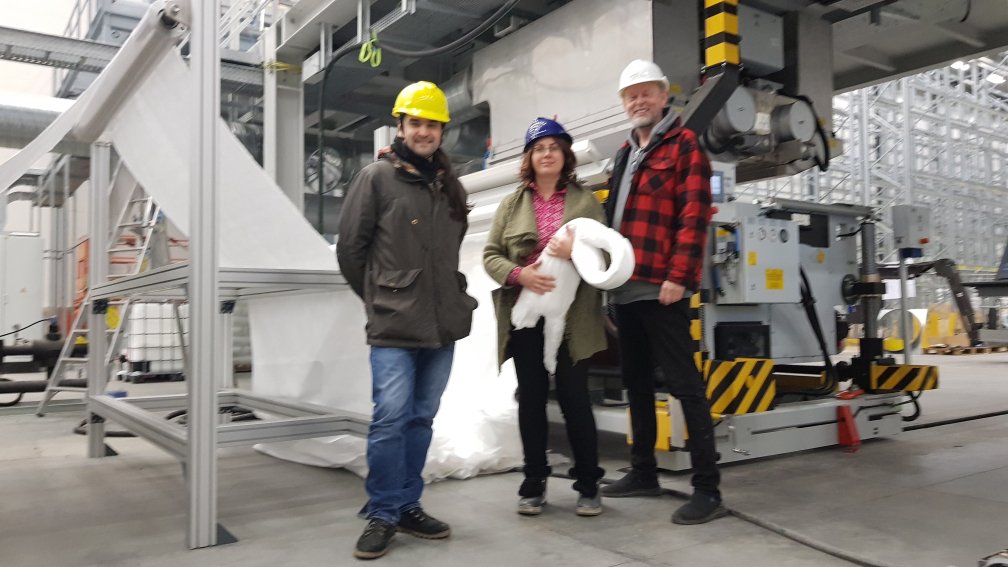

Naukatek AS was founded by nanotechnologist Liudmila Ilyukhina, polymer production specialist Ilya Gorelkin and serial entrepreneur, Stein Inge Haaland in March 2020, in direct response to the coronavirus.

The goal was to make Norway self-sufficient in the critical meltblown filter material it needed for facemasks for the country’s healthcare workers and the new company moved fast – if a little too fast for the country’s government.

Shrimp farming

Liudmila had previously been involved in the successful digitalisation and optimisation of Norway’s largest healthcare interpreting services group and at the beginning of 2020 was looking to do something completely different. She and Stein were planning to establish the largest shrimp farming operation in Sri Lanka, based on all the latest digital and sustainable technologies available today. The groundwork had already been conducted at the proposed site of this operation, but then Sri Lanka closed its borders.

Back in Norway, with time on her hands as the Covid-19 pandemic unfolded, Liudmila turned her attention to the PPE shortages, which – as elsewhere – were preoccupying the country’s frontline health workers, and wondered how she could help.

“My initial idea was to build a digitalised supply chain for the effective distribution of masks produced on sewing machines in the home,” she says. “Then I started to study standards and quality issues and quickly realised that without meltblown nonwovens we were not going anywhere. Further investigations inevitably led me to Reicofil, as the specialist in the technology for this field.”

After fruitful discussions with Reicofil, Naukatek was quick off the mark to make the deposit on a new meltblown line, signing the contract at the beginning of April 2020 – ahead of the many new meltblown investments that were subsequently announced, leading to a period of backlogs, initially as long as 18 months for Reicofil, and other INDEX™20 exhibitors specialising in meltblown technology, such as Germany’s Oerlikon and Italy’s Ramina.

Knowledge keeper

Naukatek took delivery of a 1.6 metre wide standalone Reicofil meltblown machine – a first for Scandinavia – in September, having already installed a facemask converting machine at its new plant in Trondheim.

The converting line has a monthly capacity of three million facemasks – more than enough to meet the needs of a country with a population of just 5.4 million people. The remainder of the meltblown material capacity – 40 tons per month – was made available for the general market to help out other countries with PPE shortages.

“We quickly drew on our expertise to create the range of FFP2, FFP3 and N95 standard facemasks we are still selling and have also helped many of our customers who themselves were start-ups, in achieving the necessary properties and constructions for their facemasks, because a lot of what was being made was not meeting the necessary standards,” Liudmila says. “We have become the knowledge keeper for all modes of facemask.”

By the time Naukatek had started up its meltblown production, however, China and other countries in Asia were also rapidly increasing production, and prices on the open market began to fall.

The company has been disappointed at the lack of support from the Norwegian government and its subsequent return to sourcing facemasks from Asia.

“There was a lot of talk by European governments about becoming self-sufficient during the shortages, but we have been frustrated by what’s happened subsequently,” Liudmila says. “Norway is not in the European Union but follows its procurement policies and it appears that there’s a fear of not breaking any laws in respect of international trade, but this is always only based on price in the end. No other criteria are taken into account.

“This was a real opportunity to secure European jobs and knowledge, as well as self-sufficiency in essential PPE, but it hasn’t been taken – even in Germany, where new companies have been heavily subsidised, sourcing is taking place internationally and is based purely on price. Facemask machines are now being scrapped as a result.”

New ideas

Undaunted, Naukatek has been drawing on its research credentials to decide what can be done with meltblown technology next.

“I can’t share too many details, but we are developing completely new materials for high-tech applications in the electronics industry,” Liudmila reveals. “They are based on some very meaty new ideas and the application promises to be a breakthrough. We have had the freedom to research and now just have to be faster than the rest. Hopefully we’ll be in a position to say more very shortly.”