In January last year, unfamiliar new smart recycling bins started to appear outside selected Etos grocery stores and Companay & Partou day-care centres in Amsterdam.

They represent the latest visible initiative by the industry in developing workable solutions for the recycling of nonwoven-based absorbent hygiene products (AHPs).

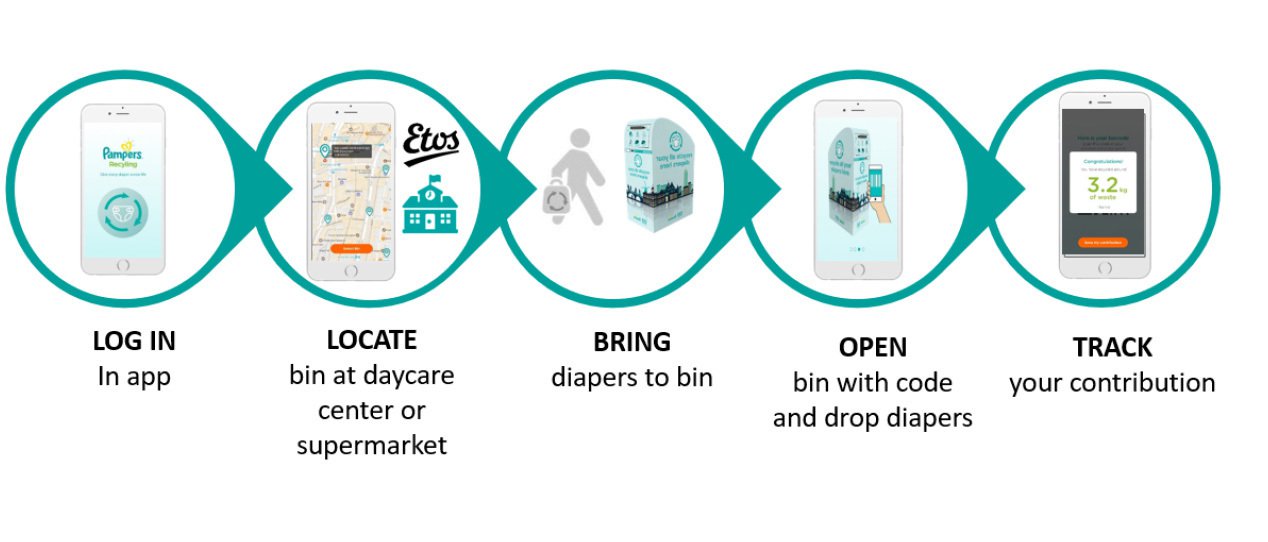

Installed by Procter & Gamble, Terracycle, AEB and FaterSMART as part of the EU Horizon 2020 Embraced Project, they can be opened through a special mobile app, which locates the nearest available bin and generates a bar code to unlock it. After depositing their AHP waste, consumers can track their personal contribution to the environment, as well as the collective contribution of their neighbourhood.

Over 1,800 people have so far downloaded the app and 400 families are now actively using the bins, which are emptied two or three times a week, with the quality of the waste collected said to be very high and containing less than 2% non-targeted material.

Italian success

This follows the successful establishment of the first AHP recycling plant in Contarina, Italy, which is being operated by FaterSMART, a subsidiary of Fater, the Italian joint-venture between Procter & Gamble and Angelini, with an annual capacity of 10,000 tons.

From a pilot plant in 2013, the Contarina operation moved to demonstration scale in 2015 and to fully working industrial operation in 2017.

Its success has now led to the signing of Italy’s End of Waste Decree in May 2019, establishing the criteria allowing materials deriving from the recycling of diapers and femcare products to be transformed and qualified as secondary raw materials that can be returned into the production process. This is a worldwide first, and it is anticipated that a further 60 micro-plants will now be created throughout Italy, with the creation of over 1,000 new jobs.

Enrico Dolce, FaterSMART product development and sales manager, outlined the scale of the problem the industry is currently seeking to address.

Separate collection

There is, he said, some 30 million tons of AHP waste sent to landfill or for incineration globally each year, with 8.5 million tons of it generated in the EU and 900,000 tons in Italy alone.

As a result of the Contarina operation and its support system, however, over one million people are now being served with separate AHP waste collection in Italy.

The success of further micro-plants, Dolce said, will rely on a similarly interlinked structure, needing local authorities to be willing to put in place the segregated collection of the AHPs and waste operator partners willing to invest and operate them.

The technology in place at the Contarina plant has been 3rd party certified for safety in terms of its microbiological sterilization efficacy, with steam penetration into every part of the waste. It also effects the full degradation of any drug residuals.

All of the main components of AHPs are recovered, with the sterilized plastic components being recycled into hard plastic products such as pallets and furniture. The sterilized cellulose finds second life as a viscose fibre component as well as in applications such as seed bed mats, cat litter and paper, while the superabsorbent polymer can be used in products such as industrial absorbers, pet mats and as an industrial densifier.

Beyond recycling

The Embraced Project, however, which involves 13 partners in seven EU countries, is now exploring moving beyond recycling to upcycling, with the establishment of an integrated biorefinery in Amsterdam.

“Our research activity is now focused on the identification of new high added value applications for the secondary raw material produced through the recycling process,” Dolce said. “Our focus is particularly on the promotion of the material in sub-sectors of green chemistry, composite materials and agronomy.”

Specifically, the partners are exploring the potential of turning the sterilized cellulose components of AHPs into biostimulants, medical devices and even fragrances.

“How strange,” Dolce concluded, “that a used diaper can actually be turned into a perfume?